Our company strictly controls our design, production, modification, packaging, and shipping processes in accordance with the ISO9001 quality policy.

Before production, our senior engineers analyze the parts and arrange the optimal processing technology and procedures for each part, allowing the production department to produce according to these processes and procedures.

During the production process, we control our quality in each production process. after each process is finished, our quality inspectors need to check the dimensions, if all the dimensions meet the requirements, then go ahead the next process, otherwise we have to repair the part or remake a new part.

After production is completed, we will conduct a full inspection to ensure that each dimension and feature meets the requirements of the drawings before packaging and shipping, it is 100% full inspection.

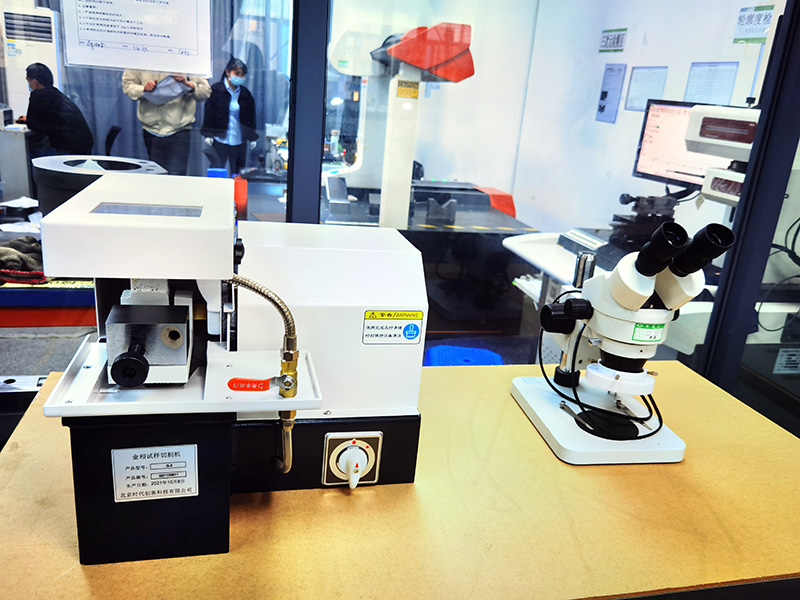

We equipped 14 sets of inspection equipment, 170 pcs inspection calipers and micrometers, the main QC equipment like CMM machine, optical projector, electronic height gauge, electronic gauge etc. In addition, we regularly inspect and calibrate our testing equipment every year to ensure accuracy.

It is the advanced measuring equipment and strict quality management that make our quality highly praised by customers.